Product design usually consists of 4 phases. Over the next few weeks we will discuss these phases and what key factors dictate the speed of each phase in relation to production. The first phase of any project is what we call the Concept phase.

In the concept phase, we decide on several key components of the project. Some of these components include:

1. What the product actually needs to be.

Determining what your product needs to be may be different that determining what your product should be. You need to understand the customer base for your product from the birth of the product design.

2. What does the product look like?

Understanding what your product should look like aesthetically and functinally is also a key component. Is it a big product that needs special packaging? Is it a fragile product that needs extra packaging consideration? Does the look of the product effect its’ marketability? Does your product look like the competitors product or is it unique to the industry? These are just a few example questions you should be asking yourself about the way your product looks.

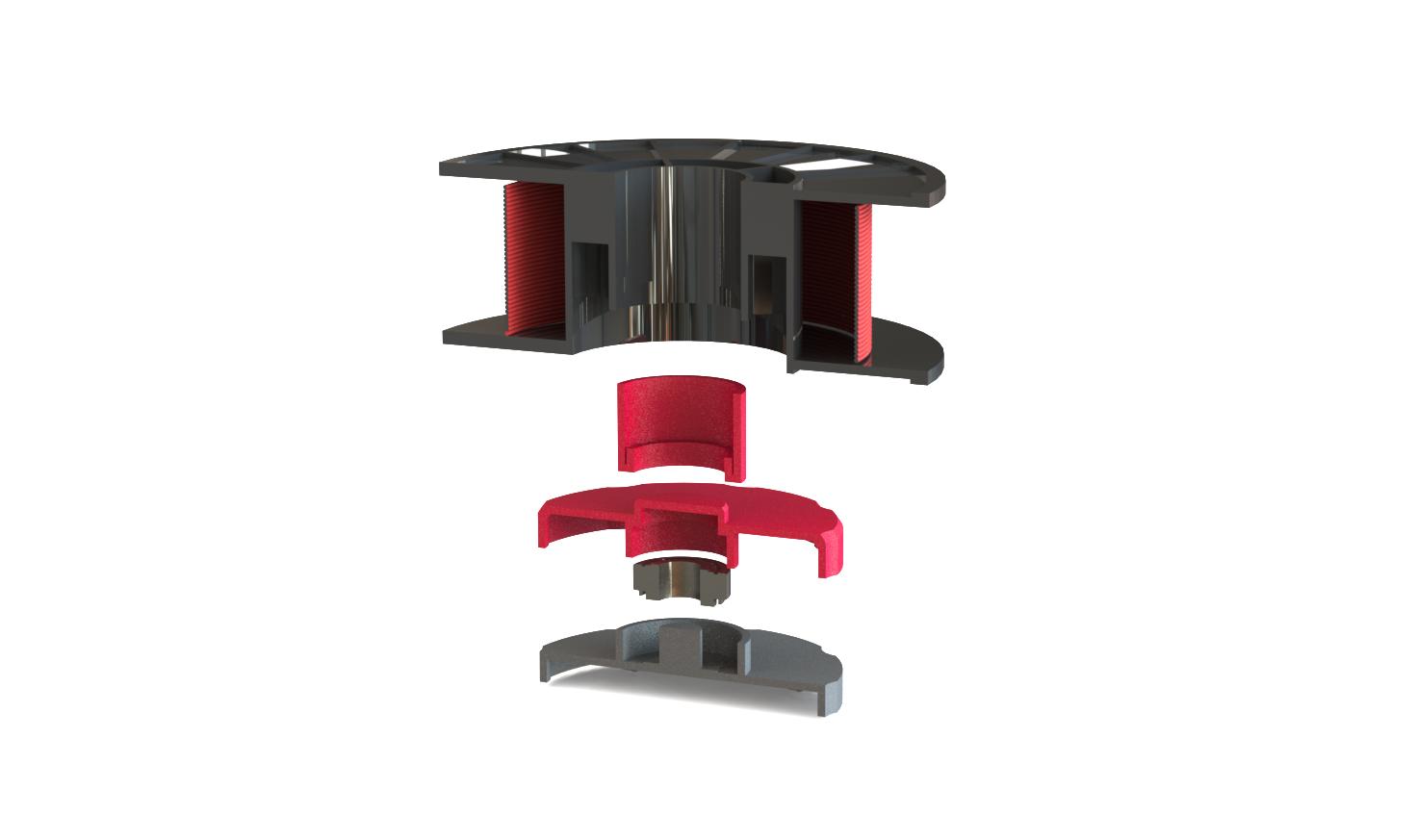

3. What material is the product made from?

Understanding the material options for your product can be a daunting task. We typically recommend having a base idea for the material selection such as wood, plastic, metal, aluminum. Common plastic materials include ABS, Polycarbonate, Polypropylene, Nylon, HDPE, and even ASA. There are of course exotic variances of each of these materials as well as additives that can be combined to improve certain qualities. When customers work with Level, LLC, we make sure that the right material for your product is used. Cost, weight, structural integrity, and looks all play a factor in your material selection.

4. Where do we think we will have the product manufactured?

For several years now, there has been a lot of questioning from our clients on where their product can or should be made. There are certainly US injection mold makers out there. China still remains quite competitive in the injection mold business though. Level, LLC can help you to determine the best fit for manufacturing whether it is US sourced injection molding, China sourced injection molding, or just a neighboring Country such as Canada for injection molding.

5. Who can help me bring my product to reality?

This may be the biggest question of all for many. Choosing a great design firm or individual can be very difficult. There are many factors that need to be considered when you choose your vendor: Do they charge by the job or by the hour? Do they have good resources for manufacturing? Do they have good referrals?? How long have they been in business? Can you reach the owner and do they participate in the project?

For more information, contact us for a personal consultation.