In our last post, we discussed the first phase of product design and the important questions that needed to be considered when starting your project. In this post, we will continue that discussion more in depth and expand on what phase 2 of your product design should look like.

In phase 2 you will already have decided on what initial resources you will need to begin the development of your product. You will likely have had several discussions with a design house such as Level, LLC or a in individual consultant. One important decision to make here is what your budget for the project should be. A thorough and well-seasoned design house should be able to give you realistic numbers for your budget considerations. It is not uncommon for injection mold vendors to shy away from giving you ballpark estimates on their tooling which is why some of them have resorted to what would seem to be convenient online quoting tools. This helps to filter or even eliminate some potentially long conversations over the phone with new customers.

Level, does not endorse the practice of online quoting and it is highly recommended that you choose a vendor, especially with injection molding, that has a US representation and someone that you can speak with over the phone or that you choose a seasoned design house such as Level to act on your behalf. Being able to discuss your idea or project with someone is a crucial step in your product design. Using a company like Level gives you the advantage of having a personal assistant and advocate for your project. We can help guide you through the conversations that you should be having with the injection mold company or, if preferred, we can be your complete representation with them.

During Phase 2, you will begin to layout the concept of you product or parts with the design team. They will help you to identify any special needs such as materials, specialized vendors in metal or plastics manufacturing, and finally what that magical budget should be. If you don’t have those answers by phase 2, you need to seriously consider moving to a new consultation such as Level, LLC.

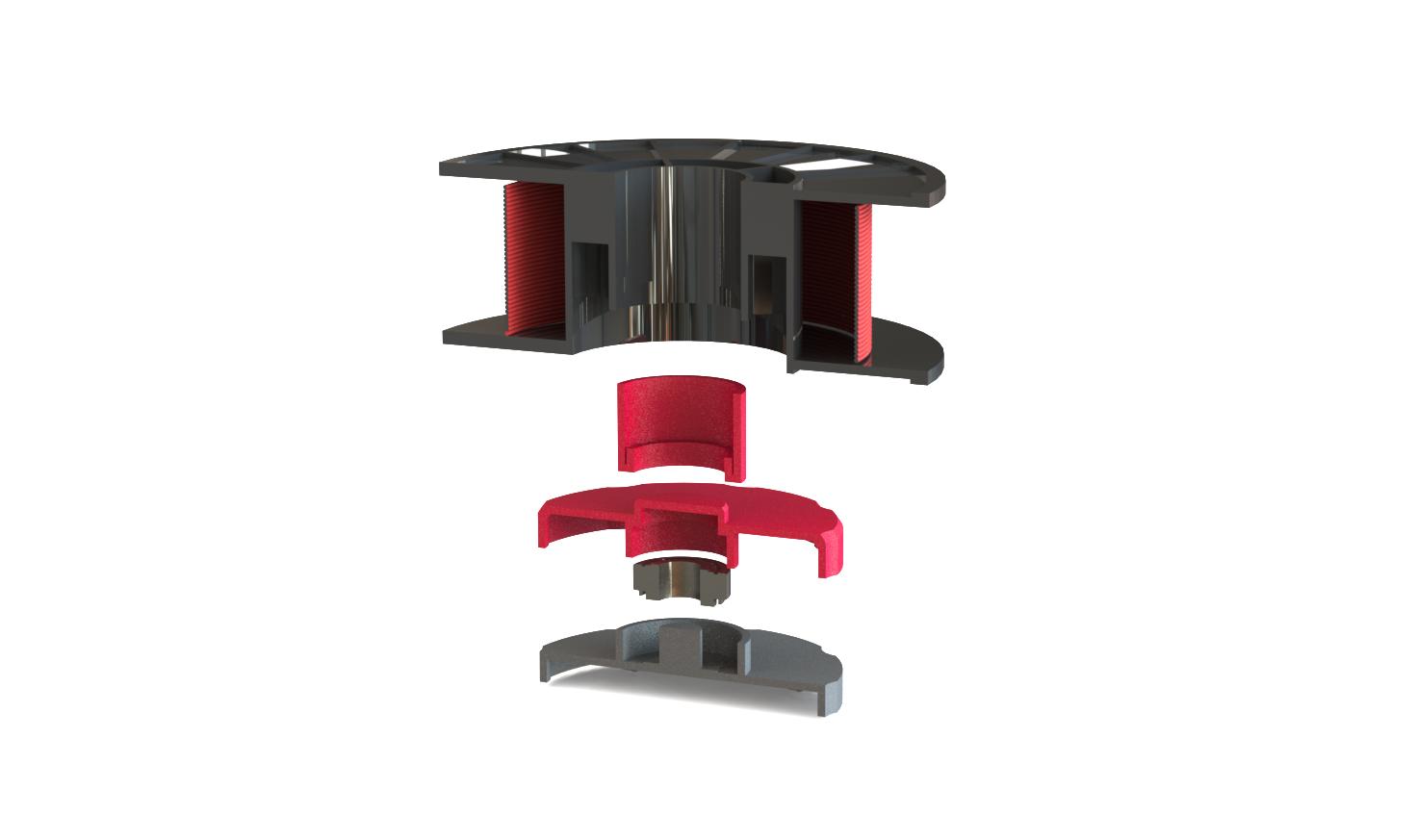

The biggest step in phase 2, after the budget is presented for your product design, is actually starting the conceptualizing of your product. This will include initial renderings, rough layouts, and some dimensional considerations.

In our next post, we will discuss phase 3 of product design. In phase 3, a lot of progress is made towards developing your product, including some prototyping. Phase 3 is arguably, the most exciting phase prior to production!